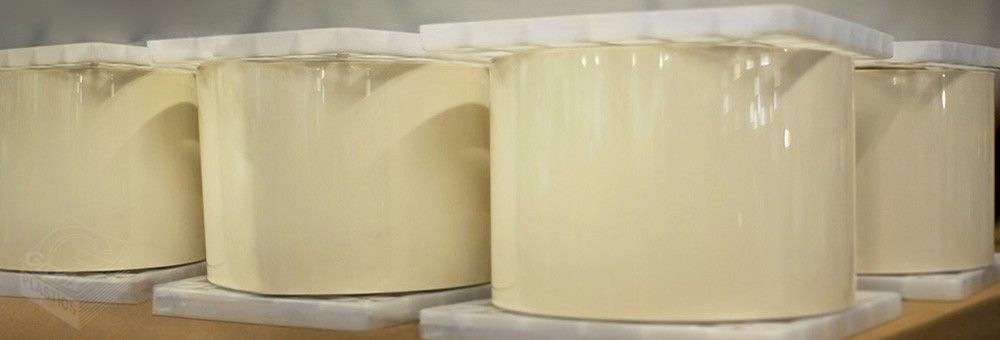

Hazy DuraLar® is a tough general purpose polyester film base with a hazy translucent finish. Hazy DuraLar’s durable physical and electrical properties make it the ideal choice for all kinds of industrial applications.

Applications for Hazy DuraLar include but are not limited to: wire, cable and motor insulation, transfer film base, casting and release liner, reinforcing composite constructions, laminating films, and more. Of course, our favorite application is our own Hazy Laser – stack laser cut-able stencil film!

Features

- Excellent balance of mechanical properties

- Good thermal stability

- Extra dielectric strength

- Resistant to a wide range of chemicals

Stock

- .005″/125um – 60″ mostly, 36″ sometimes, custom widths available.

- .010″/250um – 60″ mostly, custom widths available.

- .014″/325um – Check with us to see what we have.

Other thicknesses of Hazy DuraLar are available but not in stock. Contact us for more information.

Sheets, rolls, and packs of Hazy DuraLar are made to order, but not kept in stock.

Check out our extensive converting services pages for a full range of converting options. Like all our other film products, Hazy DuraLar can be sheeted or slit to your size requirements!

Not sure you’re seeing what you need? Please start an inquiry today!

Specs

Properties are based on .010″/250um general use Hazy DuraLar polyester film. Properties of other gauges and finishes of DuraLar polyester film can vary.

| Film Property | Value | Units | Test Method | ||

|---|---|---|---|---|---|

| Physical Properties | |||||

| Tensile Strength (MD) | 27000 | psi | ASTM D 882 | ||

| Tensile Strength (TD) | 27000 | psi | ASTM D 882 | ||

| Strength Elongation MD | 15000 | psi | ASTM D 882 | ||

| Strength F-5 TD | 14000 | psi | ASTM D 882 | ||

| Modulus MD | 710000 | psi | ASTM D 882 | ||

| Modulus TD | 740000 | psi | ASTM D 882 | ||

| Elongation MD | 150 | % | ASTM D 882 | ||

| Elongation TD | 150 | % | ASTM D 882 | ||

| Density | 1.4 | g/cc | ASTM D 1505 | ||

| Water Absorbtion | 0.55 | % | ASTM D 1505 | ||

| Service Temp | -70 to 150 | Deg C | Internal | ||

| Electrical Properties | |||||

| Dielectric Constant | |||||

| 25°C, 1 kHz | 2.6-3.7 | ASTM D150-81 | |||

| Dissipation Factor | |||||

| 25°C, 1 kHz | 0.0015 | ASTM D150-65 | |||

| Volume Resistivity 25°C | 1.0E+16 | ohm-cm | ASTM D257-78 | ||

| Surface Resistivity | 1.0E+12 | Ohm | ASTM D257 | ||

| Termal Properties | |||||

| Shrinkage @ 150C- MD | 1.2 | % | ASTM D1204 | ||

| Shrinkage @ 150C- TD | 0.04 | % | ASTM D1204 | ||

| Shrinkage @ 190C- MD | 2 | % | ASTM D1204 | ||

| Shrinkage @ 190C- TD | 1 | % | ASTM D1204 | ||

| Melting Point | 255 | Deg C | DSC | ||

| Service Temp | -70 to 150 | Deg C | |||

| Specific Heat @ 25C | 0.32 | Cal/g/C | |||

| Chemical Resistance | |||||

| Dilute acids and Alkalis | Good | ||||

| Concentrated Alkalis | Poor | ||||

| Concentrated HCL | Fair | ||||

| Concentrated H2SO4 | Poor | ||||

| Greases, oils, & Fats | Good | ||||

| Organic Solvents, Alcohols | |||||

| and Hydrocarbons | Good | ||||

| Keytones, Esters and | |||||

| Chlorinated compounds | Fairly Good | ||||

| Phenols, Cresols and | |||||

| Chlorinated Phenols | Poor | ||||

| Household cleaners | Good | ||||

| Optical Properties | |||||

| Haze | 93 | % | |||

| Refractive Index | 1.65 | RI | |||

Safety

- Hazy DuraLar meets UL Flame Class VTM-2, contact us for more details.

- DEHP, DBP and BBP free. Contact us for more details.

- RoHS Compliant

- Meets MilSpec L-P-377C Type I

Our experts are ready to help make your job easy! Please contact us with your requirements today by starting an inquiry.