Protecting critical surfaces is important. Wouldn’t it be great if everything had a diamond-hard (or some other unobtainum) coating on it? No surface would ever get scratched, marred or permanently stained with dirt. Unfortunately, not everything is made by Tony Stark! That’s where Grafix Plastics’ surface protection films comes in.

Often it’s hard to find the right kind of protection film, one that’s easy to apply and remove. That’s where Grafix comes in! We offer several general purpose surface protection films that work well in a wide variety of industrial applications. And, because our protective films are not self-wound, but have a convenient release liner backing, our films can be supplied in cut-to-size sheets, as well as rolls.

Features

- Easy to cut

- Repositionable

- Paper liner backing

- Moisture-proof

- Easily removable

- Leaves no residue

- Screen-printable

- Excellent clarity

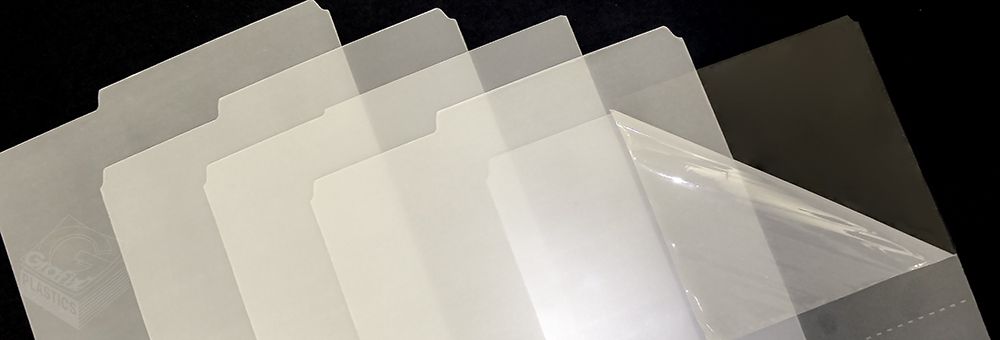

Types

Low Tack Clear (LTC): This .002” film has an ultra-removable adhesive on a polypropylene base. The adhesive sticks when needed and removes without leaving a residue. It has a low resin content and therefore offers good clarity. The polypropylene base provides excellent chemical resistance.

Low Tack Matte (LTM): This .002” film has an ultra-removable adhesive on a polypropylene base. The adhesive sticks when needed and removes without leaving a residue. Because of its matte surface, it has good anti-marring properties. The polypropylene base provides excellent chemical resistance.

Extra Tack Matte (ETM) is a .001″ matte polyester film with a stronger removable adhesive to help prevent paint seepage and edge build-up. Because of its matte surface, it has good anti-marring properties. The polyester base provides excellent chemical resistance.

Surface protection materials can also be custom-manufactured in a variety of adhesions, thicknesses, colors, and with unique properties such as anti-static, UV- protected, laser-resistant and flame-retardant. They can also be customized for a specific surface and to withstand specific fabrication processes.

All our stock surface protection films come on a thin paper release liner, which allows us to convert this film into the form you need it for direct application. However, we can also supply liner-free self-wound rolls on a custom basis.

Stock

Looking to get something quickly? We’ve got you covered with the following Surface Protection materials in stock and ready to go.

Raw Materials

Master Rolls (by width)

| Type | 10″ | 12″ | 24″ |

|---|---|---|---|

| Extra Tack Matte | • | • | • |

| Low Tack Matte | • | • | • |

| Low Tack Clear | • | • | • |

Finished goods stock sizes:

Sheets

| 18 x 24″ | 20 x 25″ | 20 x 27″ | 20 x 50″ | 24 x 36″ | 25 x 40″ | 27 x 40″ | 30 x 40″ | |

|---|---|---|---|---|---|---|---|---|

| Extra Tack Matte | • | • | ||||||

| Low Tack Clear | • | • | ||||||

| Low Tack Matte | • | • | ||||||

Rolls

| 12″ x 4 yds | 24″ x 4 yds | 24″ x 10 yds | 24″ x 15 yds | |

|---|---|---|---|---|

| Extra Tack Matte | • | • | • | • |

| Low Tack Clear | • | • | • | • |

| Low Tack Matte | • | • | • | • |

Packs

| 8.5 x 11″ | 9 x 12″ | 10 x 12″ | 11 x 14″ | 14 x 17″ | 18 x 24″ | |

|---|---|---|---|---|---|---|

| Extra Tack Matte | • | • | ||||

| Low Tack Clear | • | • | ||||

| Low Tack Matte | • | • |

Custom gauges and configurations are available with certain minimum quantities ordered.

Specs

| Phyical Properties | Low Tack Clear | Low Tack Matte | Extra Tack Matte | Tollerence | Note | |||

|---|---|---|---|---|---|---|---|---|

| Thickness | ||||||||

| FaceStock | PP, .0025″/65um | PP, .0025″/65um | PET .002″/50um | +/-5% | ASTM D 3653 | |||

| Adhesive | .001″/25um | .001″/25um | .001″/25um | +/-10% | ||||

| Liner | Clay coated kraft paper | Clay coated kraft paper | Polycoated Paper | +/-5% | ||||

| Thickness | +/- 5% | |||||||

| Tear strength | 270 | 270 | mN | |||||

| Burst-Mullen | 155 | 155 | kpa | |||||

| PSA Adhesion Properties | ||||||||

| Low (3N/25mm2) | Low (3N/25mm2) | Med (58N/m) | ||||||

| Usage Characteristics | ||||||||

| Application Temp Min. | 40 Deg. F/(5 deg C) | 40 Deg. F/(5 deg C) | 40 Deg. F/(5 deg C) | |||||

| Service Temp | -40 F to 140F/-40C to 60C | -40 F to 140F/-40C to 60C | -20F to 140F/-30C to 60C | |||||

| Moisture & Humidity | Good | Good | Good | |||||

| Sunlight & Weather | Very Good | Very Good | Good | Note: Not UV Stablized facestock. | ||||

| Heat resistance | Moderate | Moderate | Good | |||||

| PH Value | Neutral | Neutral | Neutral | |||||

For more specific questions regarding Surface Protection Films, please contact your sales representative today!

Important Notice: Grafix makes no warranties, express or implied, including but not limited to any implied warranty of merchantability of fitness for a particular purpose. The user is responsible for determining whether the Grafix product is fit for a particular purpose and suitable for the user’s method of application. Please remember that many factors can affect the use and performance of a Grafix Plastics film product in a particular application. Given the variety of factors that can affect the use and performance of a Grafix product, some of which are uniquely within the user’s knowledge and control, it is essential that the user evaluate the Grafix product to determine whether it is fit for a particular purpose and suitable for the user’s method of application.

Limitation of Remedies and Liability: If the Grafix product is proven to be defective, THE EXCLUSIVE REMEDY, AT GRAFIX’S OPTION, SHALL BE TO REFUND THE PURCHASE PRICE OF OR TO REPAIR OR REPLACE THE DEFECTIVE GRAFIX PRODUCT. Grafix shall not otherwise be liable for loss or damages, whether direct, indirect, special, incidental or consequential, regardless of the legal theory asserted, including, but not limited to, contract, negligence, warranty or strict liability.

Safety

- DEHP, DBP and BBP free. Contact us for more details

- RoHS Compliant. Contact us for more details

To learn more about how our protective films can help you lower scrap and damage rates for your critical surfaces, check out our FAQ. When you’re ready to order, contact us by starting an inquiry.